PHM Data Challenge

Call for Participation

***The PHM Data Challenge Competition is now closed and no more submissions are being accepted. Winners will be notified soon and final scores posted on this webpage. ***

** Final Results **

(Updated 12-September-2016)

| S. No. | Team # | Final Score |

|---|---|---|

| 1 | KSL | NA |

| 2 | PaHaMer | 90.01 |

| 3 | Squirrel | 84.46 |

| 4 | Cranthena | 82.32 |

| 5 | SNU-SHRM | 85.86 |

| 6 | Apocalypse | 90.05 |

| 7 | TCSEXP | 85.76 |

| 8 | Maxtropy | NA |

| 9 | ZXN-YJX | NA |

| 10 | DataMotor | 89.98 |

| 11 | Tj609 | 86.92 |

| 12 | X1 | 89.01 |

| 13 | data2016 | 83.57 |

| 14 | F&F | 88.89 |

| 15 | Flash | NA |

| 16 | DataMinors | NA |

| 17 | ShuChiML | 88.00 |

| 18 | ATP | NA |

| 19 | DataHacker | 75.15 |

| 20 | Swayam | 71.62 |

| 21 | Rogue Suadron | NA |

| 22 | Team Titan | NA |

| 23 | V8_ORIGINAL | NA |

| 24 | PDX | 74.89 |

Validation Test Data

The validation set for the PHM Data Challenge can be accessed here.

Please still use the original test set in submissions leading up to the last week. The validation set will only be evaluated once at the end of the contest. The validation set is your final submission. The validation set result is used in the final score not the test set. Also include in your final submission, documentation explaining of how your algorithm utilizes physics-based modeling. You can still submit original test set submissions on Aug 29 and Sept 5.

New! Validation and Test Set Answers

The validation and test set answers of the data challenge are now online!

Teams

Collaboration is encouraged and teams may be comprised of one of more students and professionals. The team judged to have the first, second, and third best scores will be awarded prizes of $600, $400, and $200 respectively contingent upon:

- Having at least one member of the team attend the PHM 2016 Conference

- Presenting the analysis results and technique employed at a special session within the Conference program

- Submitting a peer-reviewed conference paper (Submission of the challenge special session papers is outside the regular paper submission process and follows its own modified schedule.)

- The top entries will also be encouraged to submit a journal-quality paper to the International Journal of Prognostics and health Management (ijPHM).

- The organizers of the competition reserve the right to both modify these rules and disqualify any team for any practices it deems inconsistent with fair and open practices.

Registration

Teams may register by contacting the Competition organizers (justinian.rosca@siemens.com and nicholas.c.propes@seagate.com) with their name(s) and a team alias under which the scores would be posted.

Please note: In the spirit of fair competition, we allow only one account per team. Please do not register multiple times under different user names, under fictitious names, or using anonymous accounts. Competition organizers reserve the right to delete multiple entries from the same person (or team) and/or to disqualify those who are trying to “game” the system or using fictitious identities.

Key Dates

| Key Dates | |

|---|---|

| Competition Open | 15 May 2016 |

| Final Validation Set Posted | 22 Aug 2016 |

| Competition Closed | 8 Sep 2016, noon PST |

| Preliminary Winners Announced | 12 Sep 2016 |

| Winners Announced | 29 Sep 2016 |

| Winning Papers Due | 30 Sep 2016 |

| PHM Conference Dates | 2-6 Oct 2016 |

System and Data Description

This year’s challenge is focused on the combination of physics-based modeling and statistical approaches for prediction. It is not required that the solution you select use a physics-based modeling approach. However, additional points will be given to those approaches that provide some physical connection to the data such as health states of various components, relationship between data and model parameters / states, etc.

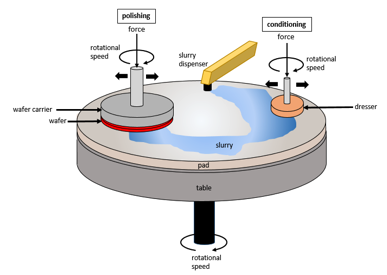

The system under investigation is a wafer Chemical-Mechanical Planarization (CMP) tool that removes material from the surface of the wafer through a polishing process. Figure 1 depicts the CMP process components and operation. The CMP tool is composed of the following components:

- a rotating table used to hold a polishing pad

- a replaceable polishing pad which is attached to the table

- a translating and rotating wafer carrier used to hold the wafer

- a slurry dispenser

- a translating and rotating dresser used to condition a polishing pad.

Figure 1: Chemical Mechanical Planarization (Polishing) of wafer. This process removes material from wafer surface.

A wafer is placed on the underside of a wafer carrier in the CMP tool, the CMP tool recipe is set (e.g. set-points for speeds, forces, polish time, etc.), and the polishing process is started. During the polishing process, the wafer is pressed against a polishing pad and both the wafer / wafer carrier and polishing pad / table are rotated in the same direction. A slurry composed of abrasive materials and chemicals are dispensed onto the pad during the polishing process. After polishing is completed, the polishing pad may be conditioned to improve its polishing properties by using a dresser. The dresser is typically composed of a hard material such as diamond that is pressed across the pad to roughen the pad’s surface to prepare it for future polishing operations.

During the polishing process, the polishing pad’s ability to remove material is diminished. Over time, the polishing pad has to be replaced with a new pad. Similarly, the dresser’s capability to roughen the polishing pads is also reduced after successive conditioning operations and after a while the dresser must be replaced.

Objective

The primary objective of this challenge is to predict polishing removal rate of material from a wafer using physics-based modeling methods and the data provided. The condition of the polishing pad and dresser change over time as they are being used. If these states can be estimated, then polishing time estimates can possibly be improved.

Data Description

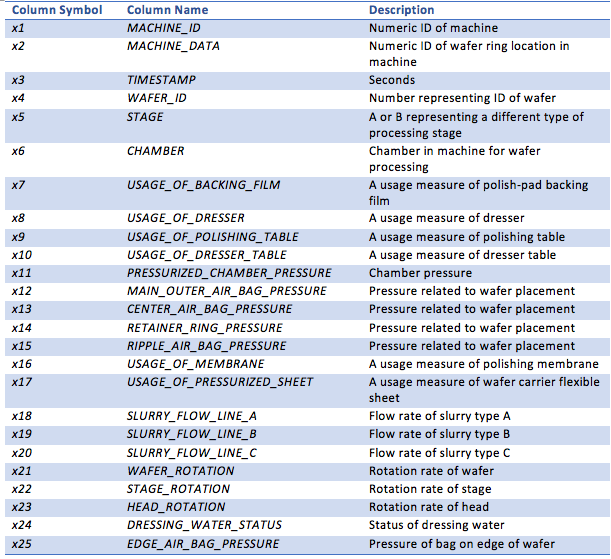

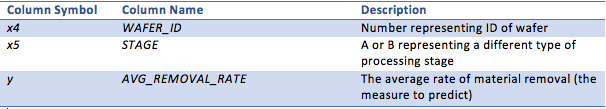

Training and test data sets are provided to you to establish your methods. The training data represents data collected during various runs of the CMP tool for specified wafers over time. Data is given in the Table 1 format described below. Each row of the data represents an instance of all measurement variables at any given time. An average rate of material removal from a wafer is given separately in Table 2, which has a corresponding wafer identification number and stage. The average rate of removal was determined from measurements of the thickness of the material before and after CMP polishing.

Table 1: Time Series Data Description

Table 2: Average Material Removal Rates

The competition training data and the test data is available here!

Questions about the data challenge should be emailed directly to the organizers (nicholas.propes@seagate.com and justinian.rosca@siemens.com). A summary of the question asked and the answer will be posted for all participants on the PHM society Data Challenge general discussion web page: https://www.phmsociety.org/forum/5182

Acknowledgement: We would like to thank Steve Mossey from Savigent for support for extracting the initially very large data files.

Scoring

During active competition, scoring will be calculated using mean squared error (MSE) accuracy. Only one submission will be accepted per team per week (on Monday by Noon PST deadline). Please send all submissions to Nicholas Propes (nicholas.c.propes@seagate.com).

The final submission is to include a 1-page description of the physics-based modeling method utilized (if any) and the final predicted average removal rates on a validation dataset to be posted several weeks before the competition closes.

After the competition is closed, the final score will be calculated for all submissions based on the MSE accuracy (90% weight) and the physics-based modeling approach (10% weight). The physics-based modeling approach will be judged on the following criteria:

- Estimation of dresser condition and effect on removal rate of polishing pad (3%)

- Estimation of polishing pad condition and effect on removal rate of polishing pad (3%)

- Effect of other parameters on the removal rate of polishing pad (4%)

References

- https://en.wikipedia.org/wiki/Chemical-mechanical_planarization

- https://www.crystec.com/alpovere.htm

- http://www-mtl.mit.edu/researchgroups/Metrology/PAPERS/Thesis_Xiaolin_final.pdf

- http://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=1189&context=etd

- http://escholarship.org/uc/item/4ct2n4jh

- http://homepages.rpi.edu/~schwed/Research/sundararajan_jecs_cmp.pdf

- http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.8.6597&rep=rep1&type=pdf